Well-designed barcode and labeling systems in areas such as the warehouse and distribution centers have proven effective ways to save costs by increasing worker productivity and accuracy.

Managers in these areas who have looked at their operations, analyzed the workflow for duplication and waste, studied how equipment was being used – or not used and why, are coming up with ways to drive down costs and improve productivity. Some use outside consulting to identify areas to improve and make suggestions on how to implement change with little or no interruption to daily business.

For instance, let’s look at a common task – labeling. First to mind may be the cost of labels. There are certainly ways you should be taking advantage of to lower the cost of the label without compromising the label’s performance.

There are often higher costs associated with labeling. Costs such as the cost of fixing errors when the wrong label is applied. The cost of printing more labels than needed and throwing the extra away. The cost of inventorying labels, finding them, tossing labels that have expired. There is a cost to labels that fail a barcode scan, have outdated information, or falls off the intended destination. There is even a cost to having workers go to the label printer and return to their station; more if engaging in conversation along the route.

Here are some common ways to prevent loss with simple changes in your labeling:

- Saves Time: By printing your labels when and where needed, a worker saves time running back and forth to a central printer for labels.

- Using smaller, compact printers for specialized label runs saves time doing label roll changes and interrupting long runs on the larger industrial printers. The cost to purchase a compact printer is often lower and can be placed in areas with limited available space.

- Increased Accuracy: That label is placed directly on the shelf without interruptions that can allow room for misplaced labels, or returning to the wrong bin.

- Labels printed on demand are most likely to be used before damage from storage. Printing on demand is also the best assurance the information is up to date.

- Save on Equipment costs by sharing specialized equipment such as an RFID printer that is only used on occasion or for DOD Military labeling requirements.

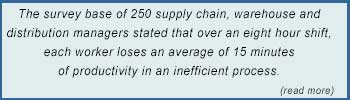

The study further shows that nearly eight out of ten warehouse managers are required to find and fix inefficiencies from existing operations.

The reality is an estimated two thirds have not done so. How about you? How much is your company loosing?

Some of the ways we can help are:

Labels and placards for marking warehouse locations

Barcode printers and printer service

Mobile carts – bring your printing right to where you need it

Mobile computers and barcode scanners

Labels of all types

To power the Intermec printer and computer in the top photo, the perfect solution would be one of our Newcastle PowerPacks.

We’ve been helping our customers improve workflow with innovative label designs, labeling workflow and barcode systems. If you are tasked with looking for cost-saving ways to improve your productivity, start with your labeling. Start with Winco ID. The call is free, so call us at 800-325-5260 X237 and learn how we can help you save.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.