With the demand for productivity and cost containment in manufacturing, it makes sense to adopt a technology that can give you reliable data for complete traceability throughout the supply chain. Using RFID technology, manufacturers can have a system in place to improve efficiency and product quality.

With the demand for productivity and cost containment in manufacturing, it makes sense to adopt a technology that can give you reliable data for complete traceability throughout the supply chain. Using RFID technology, manufacturers can have a system in place to improve efficiency and product quality.

Current RFID tags and readers can now operate effectively in many environments: extreme cold or heat, areas of high moisture, or hazardous locations. Using RFID systems, all types of manufacturers can control and monitor their processes to improve production and gain efficiencies with access to real-time data.

Here’s an overview of how manufacturers can benefit from RFID technology.

RFID on the Plant Floor

Everyone knows that tracking products through the supply chain improves product quality and customer satisfaction, but you can use RFID internally to improve process efficiency and decrease costs.

- Put RFID tags on your machines, trucks, and forklifts and you can access data telling you the contents, location, usability, and maintenance requirements of each piece of equipment

- Access real-time data and find problem areas quickly to allocate labor or assets as needed to optimize production

Inventory management

As an inventory management tool, RFID can’t be beat for giving you the accurate data you need to control costs and eliminate waste.

- Accurate tracking lets you improve forecast demands for raw materials and equipment

- Identify what items are being used or can be allocated to a specific job to improve your production scheduling

- Get an exact count of remaining supplies and their location to decrease downtime and shrinkage

Work-in-progress

Keeping records on each manufacturing processes using manual data entry takes a lot of time and is error-prone and incomplete. Use RFID to track manufacturing work-in-progress and improve workflow productivity and efficiency.

- Tag work-in-progress applications to get real-time part or product location and assembly line status updates

- Ensure that the right materials end up in the right place and at the right time to prevent downtime

- Coordinate equipment, manpower, and material resources in environments where multiple products are assembled on a single production line, or when complex products are assembled in multiple plants

- Automatically update customer data and finished goods inventory

We Can Help

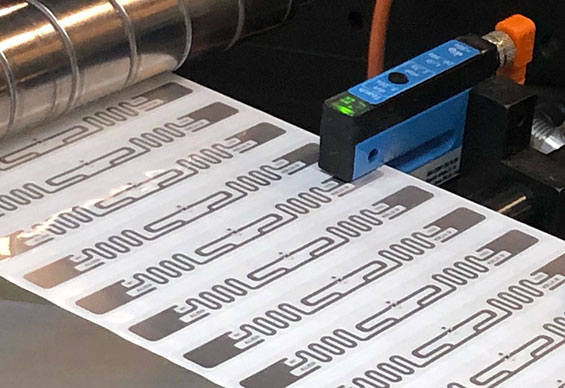

With Jet Label joining our ProMach team we can now provide custom RFID labels for many applications – just let us know what you need!

RFID has become an important tool for improving production performance and lowering costs. Are you ready to find out how RFID can help you improve your manufacturing processes? Contact us today at 888-438-3242 Option#3. You can also email me at dholliday@idtechnology.com We’ll get you in touch with one of our local experts right away.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.

Labeling & Coding News is the online industry insider from ID Technology, EPI , Panther, Greydon, and Code Tech Labeling & Coding product brands of ProMach.